Equipment Introduction

A key equipment in modern manufacturing. Controlled by computer, it precisely manages the screw fastening process with accurate parameter setting. Has an efficient feeding system and intelligent screwdriver, handles different screw types, and features a user-friendly interface for easy operation and monitoring. It boosts efficiency, quality, and reduces costs and errors, crucial for various industries to ensure product integrity.

Equipment Parameter

|

Models |

TBT5441-SXV |

|

Size: LxWxH |

750×780×950mm |

|

Movement Range: X*Y*Z |

500*400*100mm |

|

Fastening Range: X*Y*Z |

180*400*100 mm |

|

Weight |

150 kg |

|

Drive mode |

Closed-loop stepper or servo |

|

Transmission mode |

Screw rod or synchronous belt |

|

Control system |

Industrial computer with motion control card |

|

CCD Camera |

Automatic camera calibration |

|

Screw feeding mode |

Air Suction / Magnet Suction/Air Shooting |

|

Screwdriver |

Servo Screwdriver |

|

Positioning accuracy |

±0.02 |

|

Fastening time |

1.5 - 1.8s / screw |

|

Program stores |

999 Groups, 100 Points / Program |

|

Display method |

Touch Screen |

|

Supply voltage |

Single-phase 220V / 110V |

|

Power |

1350W |

|

Air supply (Mpa) |

0.5-0.7 Mpa |

|

Screwdriver Qty (Set) |

1 |

Product Functions and Highlights Analysis

1: The screw feeding method can support vacuum suction/magnetic suction (the suction nozzle needs to be replaced for switching). It can fasten stainless steel screws and spurved surfaces, and surfaces with different heights (by magnetic suction);

2: The rotation speed and torque of the intelligent screwdriver can be set on the industrial control computer with high precision (error±5%), low noise, long service life, and maintenance-free;

3: The machine adopts solid aluminum machining and sheet metal shell, with strong rigidity and high stability. The height position of the feeder and the Z-axis structure can be adjusted freely, supporting products with different heights and having strong compatibility. It is equipped with a pair of safety gratings, which is beautiful and safe.

4: It comes with an industrial control PC computer (supporting wired Ethernet/wireless Wi-Fi).

5: It supports the collection of fastening data and can be uploaded with MES for convenient later tracing (not automatically uploaded by default, and automatic upload can be selected as an option).

6: It supports code scanning for fastening(USB code scanning gun scans barcodes/ QR codes), and the fastening screw data is automatically bound to the product barcode.

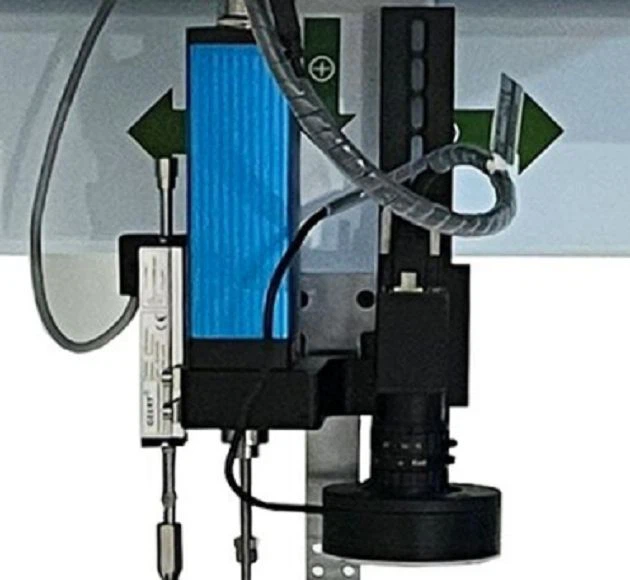

7: It supports displacement sensors (detecting floating height and automatically reversing and repairing).

8: It supports vacuum negative pressure gauges (detecting whether the screw in the suction nozzle has fallen).

9: It supports remote machine adjustment on PC and mobile terminals (an App needs to be downloaded).

10: The intelligent electric screwdriver can view the torque waveform diagram in real time.

11: It supports the later installation of visual CCD for auxiliary correction to make the screw fastening more accurate.

Exceptional Features of Intelligent Screw Fastening Equipment

I. Leading Intelligent Technology

- Industrial Computer Mastery: Utilizes advanced control tech for precise op & intelligent management. Has strong networking to connect to MES system, uploading fastening data for real-time sharing & centralized management, aiding digital production.

- Intelligent Parameter Setting & Monitoring: Via computer, set fastening data flexibly. View torque waveform in real-time to detect issues promptly, ensuring fastening quality stability.

II. Ensured Operational Safety

- Comprehensive Safety Protection Design: Equipped with safety enclosure for physical isolation and safety light curtain for intelligent monitoring. Stops running when a person enters danger zone to guarantee operator safety.

III. Enhanced Precision for Quality Improvement

- Visual CCD Assisted Precise Correction: Visual CCD system improves screw fastening accuracy. Identifies and adjusts screw position via high-precision tech, ensuring product quality.

IV. Convenient Operation to Reduce Labor Intensity

- Efficient Single-worker & Single-equipment Operation: Easy to operate, requiring one worker for loading/unloading. Equipment automates screw fastening, increasing efficiency and reducing error rate.

V. Reliable Operation for Production Continuity

- Automatic Alarm System & Long-term Stable Work: Has an automatic alarm system to monitor equipment status. Alerts for faults, and can work continuously over 20 hours, ensuring production tasks completion.

VI. Elevating Enterprise Image and Customization Service

- Shaping a High-tech Production Image: Adds vitality to the production line with advanced tech and modern design, enhancing enterprise's competitiveness and brand image.

- Personalized Customization to Meet Diverse Needs: Can be customized according to product assembly requirements, providing the best fastening solution and adapting to market changes.

Why us?

From R&D and design to batch processing of parts and then to batch assembly of equipment, we provide one-stop equipment production management. In terms of batch equipment production, we have more advantageous prices and a faster delivery cycle than our peers.

Applicable various screw shapes

The screw fastening machine is equipped with the air suction type screw feeding mechanism. This feeding mechanism has excellent versatility and can be applied to various types of screws, such as cross-head screws, Torx screws, inner-hexagon screws and slotted screws, etc.

Application Cases

Automatic screw fastening machines are widely used for Electronics, Home applications, LED bulbs, Auto parts, PCB assembly, Hardware, Computer board, toys, Furniture, etc.

Delivery, shipping and service

After - sales service is not the end, but the starting point of our eternal companionship. We are online 24 hours a day, on standby at all times, just like a guardian star, escorting you throughout your usage journey.

All the machines are with safety packing by plywooden case, solid packing ensures that the machine will not be damaged in transit.

FAQ

Q1: Why choose us?

Opt for us for several outstanding reasons. We present comprehensive processing equipment solutions. Our standard equipment inventory is extensive and readily available, guaranteeing swift shipment. Additionally, our own factory enables us to customize equipment with ease. This includes fulfilling requests for different appearances and brands for agents as well as crafting non-standard equipment in accordance with your specific requirements.

Q2: Are you a factory or trading company?

We are a factory located in Shenzhen city.

Q3: Should I worry about the quality?

Fear not. Prior to delivery, we thoroughly test the machine's working condition and provide you with a video of its normal operation. Delivery is only confirmed after your approval.

Q4: How can I know your machine is designed for my product?

You can either share the specific parameters of your product or send us samples. We will test your product on our machine and provide you with a video of the sample-testing process.

Q5: Do you provide the warranty? How about the after-sales service?

We offer a one-year warranty on the machine and lifelong technical support. Our professional after-sales team is always at your service. If you have any queries, don't hesitate to contact us.

Q6: How to operate the equipment?

My dear friend, there's no need to fret. We have created a detailed video that will guide you step by step on how to operate the equipment. If you encounter any difficulties, feel free to contact our engineers at any time. We support both video and telephone communication.

Q7: When the machine can't work well, what should I do?

Our engineers are available online 24/7. They can promptly diagnose the issues and offer you effective solutions. Rest assured that a manual will accompany the machine to ensure effortless operation.

Q8: What's the shipment terms?

We provide a variety of shipment terms including EXW, FOB, CIF, FCA, DAP, and more.

Q9: What's your payment terms?

We accept payments through T/T, VISA, Mastercard, West Union, and Paypal.

Hot Tags: robotic screwdriver machine, China robotic screwdriver machine manufacturers, suppliers, factory, benchtop electric screwdriver, screw tightening drill machine, electric screwdriver with led light usb, desktop electric screwdriver machine, robotic screwdriving, automatic screwdriver with feeder